2012

We started our activity.

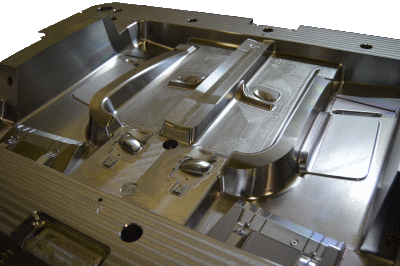

with the objective of milling parts and manufacturing moulds in response to the market's needs

We are a European mould maker with great experience and strong skills in the production of moulds for injection moulding for applications in Electrical Appliances and the Automotive sector. Managing second stage Moulds, and parts manufacturing.

We work closely with customers in order to meet their expectations in the production of moulds for the plastics industry .

We have recently changed our facilities to increase capability for the Production, in a total of 800 m2.

Our tool shop can execute and handle moulds up to 14Tn.

High Precision

Small sizes

Medium sizes

Large sizes

We always guarantee solutions for the client

We propose alternative solutions in project development

We provide effective assistance in solving the problems

We guarantee competitive prices

We manufacture moulds within negotiated deadlines

We suggest ideas and solutions in order to optimize the quality of work

Finished Projects

%

FTO Success Rate

%

Happy Customers

%

Committed to client success

We work closely with our clients in order to get the best result, which include respecting the manufacturing deadlines agreed to.

The Company's DNA is directly connected with innovation, development and expertise.

Our constant goal is to improve mould engineering solutions for several types of projects.

Our short but successful history

2012

with the objective of milling parts and manufacturing moulds in response to the market's needs

2014

with new machines and new human resources, first tool exportation to EC market

2016

we increased our installed productive capacity with further 800m2 of Production area

Some of the projects we have been working on

CNC Milling machines and other equipment

2x Portal Milling Machines Centres Correa Euro 2000

1x Portal Milling Machine Centre Deckel Maho 103 V

1x Portal Milling TRIMILL Depocut 2012

1x Milling Machine Centre Huron High Speed KX8

1x Milling Machine Centre Depo ZPS 1680

1x 5 Axis Machine Deckel Maho 125P

1x 4 Axis Horizontal Machine Centre Matec 30HV

1x Deep Drilling & Milling Machine TOS 10 CNC

1x EDM Charmilles Roboform 55P

1x Penetration EDM spark erosion

1x Grinding Machine

1x Universal Milling and Boring Machine

Software CAM worknc© 2017R1

1x Crane Up to 12,5 Tons

BenchWorksation with crane up to 8 tons, and grinding support.

We cooperate with worldwide mould makers, providing technical support once their moulds have reached Europe. This is possible due to large injections companies carrying out major moulding projects in Asia and requiring their mould suppliers to have a partner relatively close to the final manufacturing plant in Europe to offer assistance concerning any technical need.

Second stage activities are performed by Frontrunner Lda.;

Upon receiving the moulds in Portugal we proceed with the dismantling, cleaning and checking of each component individually (hardness, treatments, measurements...). A complete analysis is performed on the moving parts of the mould, cooling circuits, ejection system, etc. We proceed based on customers' logs or specifications. Once all the checks have been performed, the mould is assembled and any non-conformities are reflected in a detailed report specifying the procedure required to solve them.

Tests are performed in relation to the injection machine required by the customer. We have a selection of machines for the try out process or any kind of production stages. If a customer prefers robot tests to be performed, the robot provided by customer is used. If the mould requires texturing, tests are conducted once the mould has been assembled. Once all the tests have been conducted, the parts are packed and prepared according to customer specifications and shipped to his facilities.

If the mould requires texturing, it is dismantled in order to send the necessary components for texturing to the customer’s texture supplier. After texturing, the moulds are assembled once again.

Parts are shipped to customers for validation and final approval.

Adjustments or changes are always required during the 2nd Stage. The changes are performed by Frontrunner Lda.

When the moulds no longer require any modifications, an acceptance report is prepared in order to ship the mould to the customer’s factory. Transportation can be arranged if required.

Give us a call,we are here to help.

Have any doubts? Feel free to contact us.